Products and Services

STEEFCO factory is equipped with latest technology of the automatic CNC machineries in the world and includes the main process routes for cut and bend rebar, welded mesh, cold drawn wire and a rebar fusion Bonded Epoxy Coating (FBEC) lines.

STEEFCO fully equipped laboratory was set up to carry out continuous tests on all our products to guarantee overall performance with the required standards and customer satisfaction.

STEEFCO Services Offered:

COLD DRAWN & STRAIGHTENED CARBON STEEL WIRE

Cold drawn carbon steel wire produced by cold drawing and straightening for precise diameter, enhanced mechanical properties, and consistent surface finish. Used as raw material for welded wire reinforcement, precast, and prestressed concrete applications.

KEY SPECIFICATIONS

| Specification | Details |

|---|---|

| Standard | ASTM A1064/A1064M-24 |

| Input Diameter | 5.5 mm – 14 mm |

| Output Diameter | 4 mm – 12 mm |

| Product Form | Coil or Spool |

| Production Capacity | 10,000 tons/month |

| Wire Type | Carbon steel, cold drawn & straightened |

| Finish | Black, smooth or deformed (as per requirement) |

MECHANICAL PROPERTIES (ASTM A1064)

| Property | Requirement / Typical |

|---|---|

| Yield Strength | ≥ 485 MPa |

| Tensile Strength | ≥ 550 MPa |

| Elongation | ≥ 4% |

APPLICATIONS

- Raw material for welded wire reinforcement

- Precast concrete reinforcement

- Prestressed concrete applications

CUT & BEND REINFORCEMENT

Hot-rolled, weldable steel bars cut and bent to project-specific shapes as per BS 8666:2020. Bars comply with BS 4449:2005 +A3:2016 for material quality, suitable for reinforced concrete structures.

APPLICATIONS

- Columns, beams, slabs, and foundations

- Bridges, tunnels, and road infrastructure

- Residential, commercial, and industrial buildings

- Precast concrete elements

MATERIAL PROPERTIES

| Property | B500B | B500C |

|---|---|---|

| Yield Strength (Re) | ≥ 500 MPa | ≥ 500 MPa |

| Tensile Strength (Rm) | 540–680 MPa | 540–680 MPa |

| Rm / Re Ratio | ≥ 1.08 | ≥ 1.15 |

| Elongation (Agt) | ≥ 5% | ≥ 7.5% |

| Bend / Rebend Test | Pass | Pass |

AVAILABLE DIAMETERS

10, 12, 16, 20, 25, 32, 40 mm (other sizes on request)

SHAPES & BENDING

- Processed according to BS 8666:2020 shape codes

- Dimensional tolerances per BS 8666

- Minimum straight length between bends ≥ 4 × bar diameter

SURFACE CONDITION

- Ribs and deformations as per BS 4449 requirements

- Free from loose rust, oil, paint, or other deleterious matter

IDENTIFICATION & TRACEABILITY

- Bundle tags include bar size, shape code, length, heat number, batch number

- Mill Test Certificates (MTC) provided for traceability

PACKAGING

- Bundled, strapped, and tagged

- Delivered safely to prevent damage or corrosion

COMPLIANCE

- BS 4449:2005 +A3:2016 (Steel for reinforcement of concrete)

- BS 8666:2020 (Scheduling, dimensioning, bending, and cutting)

WELDED WIRE REINFORCEMENT (WWR) – DEFORMED WIRE MESH

Welded Wire Reinforcement (WWR) is a prefabricated steel reinforcement consisting of cold-drawn deformed steel wires electrically welded at the intersections. It is manufactured in flat sheets and used primarily for concrete slabs, pavements, walls, and precast elements.

MESH SPECIFICATIONS

| Parameter | Value |

|---|---|

| Wire Type | Deformed Carbon Steel Wire |

| Wire Diameter | 4 mm – 12 mm |

| Wire Spacing | 100 mm, 150 mm, 200 mm |

| Sheet Size | Min 2.0 × 1.0 m, Max 6.0 × 2.75 m |

| Total Mass per Sheet | As per size and wire diameter |

| Finish | Black (Deformed Surface) |

MECHANICAL PROPERTIES (ASTM A1064)

| Property | Requirement / Typical |

|---|---|

| Yield Strength | ≥ 485 MPa (70 ksi) |

| Tensile Strength | ≥ 550 MPa |

| Elongation | ≥ 4% |

MANUFACTURING COMPLIANCE

- ASTM A1064/A1064M

- Wire sourced from cold-drawn, deformed carbon steel

- Welds meet standard fusion and shear strength requirements

APPLICATIONS

- Concrete floor slabs

- Pavements and roads

- Precast concrete elements

- Wall and foundation reinforcement

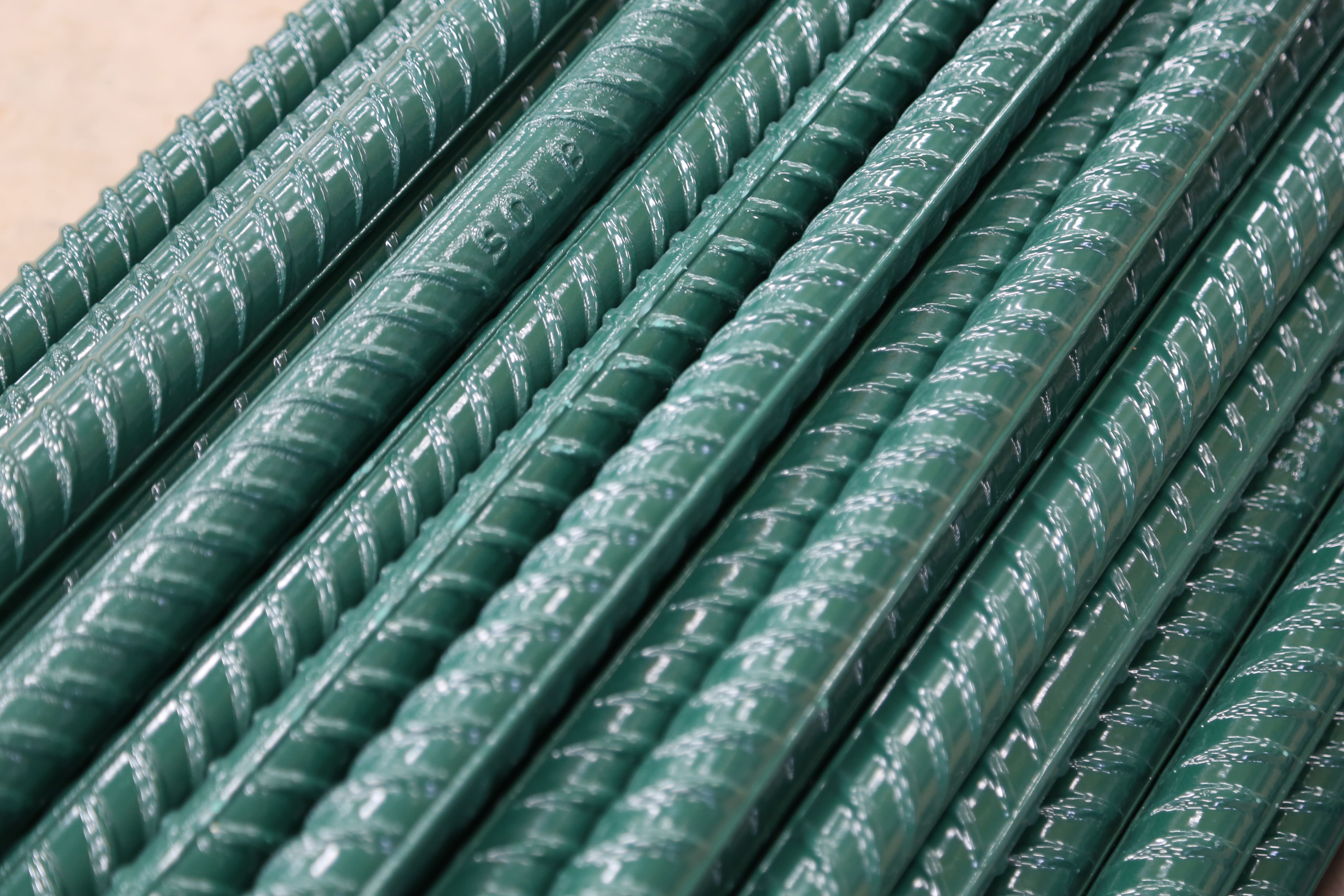

F.B.E.C EPOXY COATED RE-BARS

We provide epoxy-coated deformed steel rebars from 8mm to 40mm diameter. Fusion-bonded epoxy coating increases the longevity of reinforcing steel in corrosive environments. Standard: ASTM A775 / A775M – Fusion Bonded Epoxy Coating (RAL 6005 – Moss Green).

ADVANTAGES

- Protection: Designed to resist rust and corrosion.

- Environmentally Friendly: Contains no hazardous solvents.

- Manufactured to meet ASTM A775.

TECHNICAL REQUIREMENTS

| S.No. | Description | Standard / Requirement |

|---|---|---|

| 1 | Visual Inspection of Oil & Grease | Free of oil and grease |

| 2 | Shot Blasting | SSPC VIS 1 Standard (Near White) |

| 3 | Copper Sulphate Test | Mill scale contamination turns red |

| 4 | Chloride Test | < 10 µg/sq cm |

| 5 | Surface Contamination Tape Test | 40 – 115 microns |

| 6 | Back Contamination Tape Test | < 20% |

| 7 | Temperature of Rebars | 232 – 239 °C |

| 8 | MEK Test | No reaction of MEK solution on coating |

| 9 | Holiday Test | Max 3 holes / meter length |

| 10 | Thickness of Coating | 175 – 300 microns |

| 11 | Bending Test | Around 6D mandrel |

EPOXY COATED REBAR (ASTM A775)

| Nominal Diameter (mm) | No. of Bars per Bundle | Nominal Weight (kg/m) | Nominal CSA (mm²) |

|---|---|---|---|

| 8 | 422 | 0.395 | 50.27 |

| 10 | 270 | 0.617 | 78.54 |

| 12 | 188 | 0.888 | 113.10 |

| 14 | 138 | 1.210 | 153.94 |

| 16 | 106 | 1.580 | 201.06 |

| 18 | 84 | 2.000 | 254.47 |

| 20 | 68 | 2.470 | 314.16 |

| 22 | 56 | 2.990 | 380.13 |

| 25 | 44 | 3.850 | 490.87 |

| 28 | 34 | 4.830 | 615.75 |

| 32 | 26 | 6.310 | 804.25 |

| 36 | 20 | 7.990 | 1017.88 |

| 40 | 17 | 9.860 | 1256.64 |

.png)